Kitchen airing

All rooms that contain hobs with burners – that use up air in the room they are installed in – require airing ducts.

Airing means adding fixed combustion air inlets, i.e. open ducts which can be either in the outside walls of the room itself or in a wall that connects to an adjacent room that has a duct that leads outdoors.

Kitchen Aeration Holes

Why are aeration holes necessary?

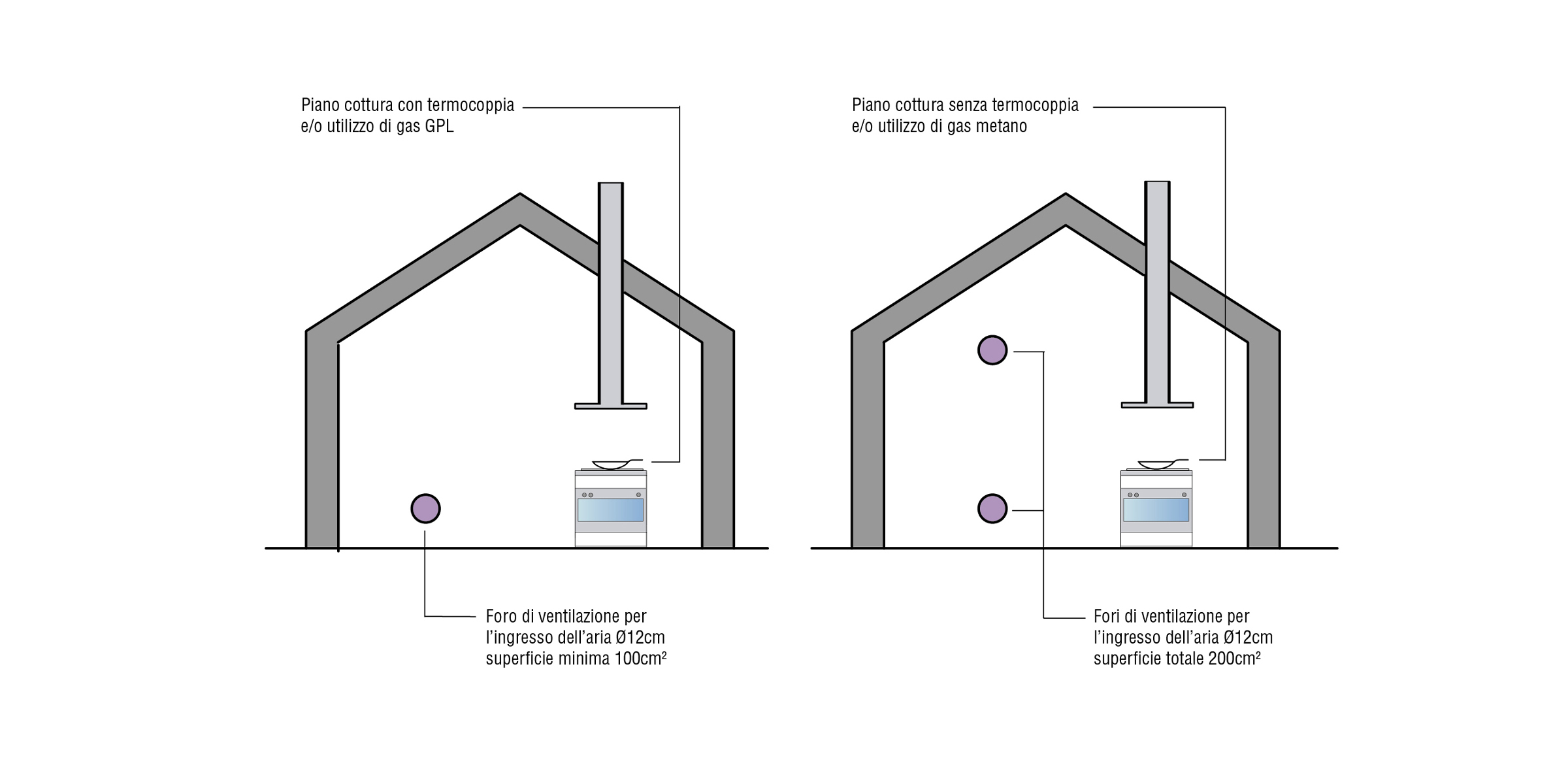

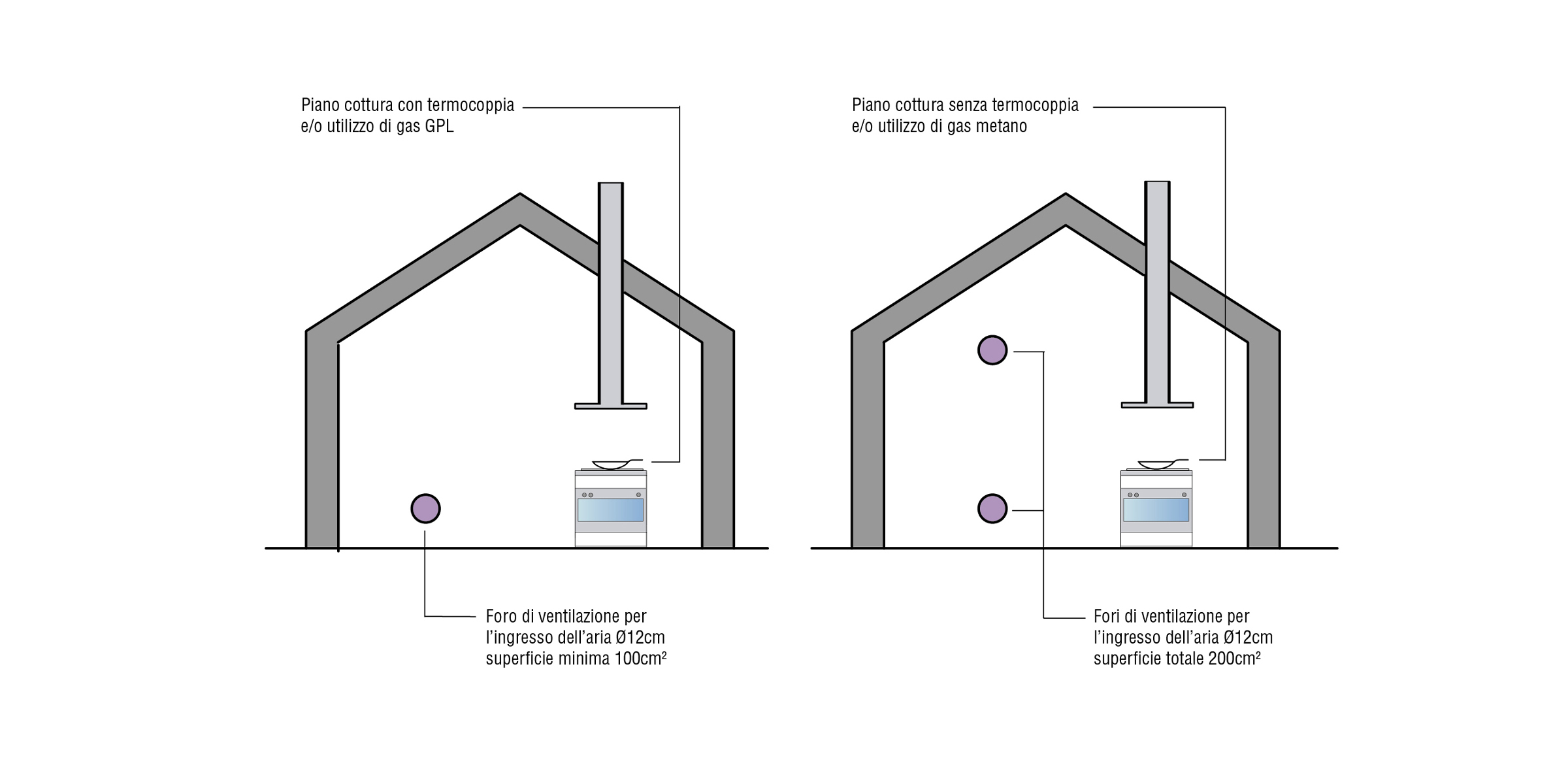

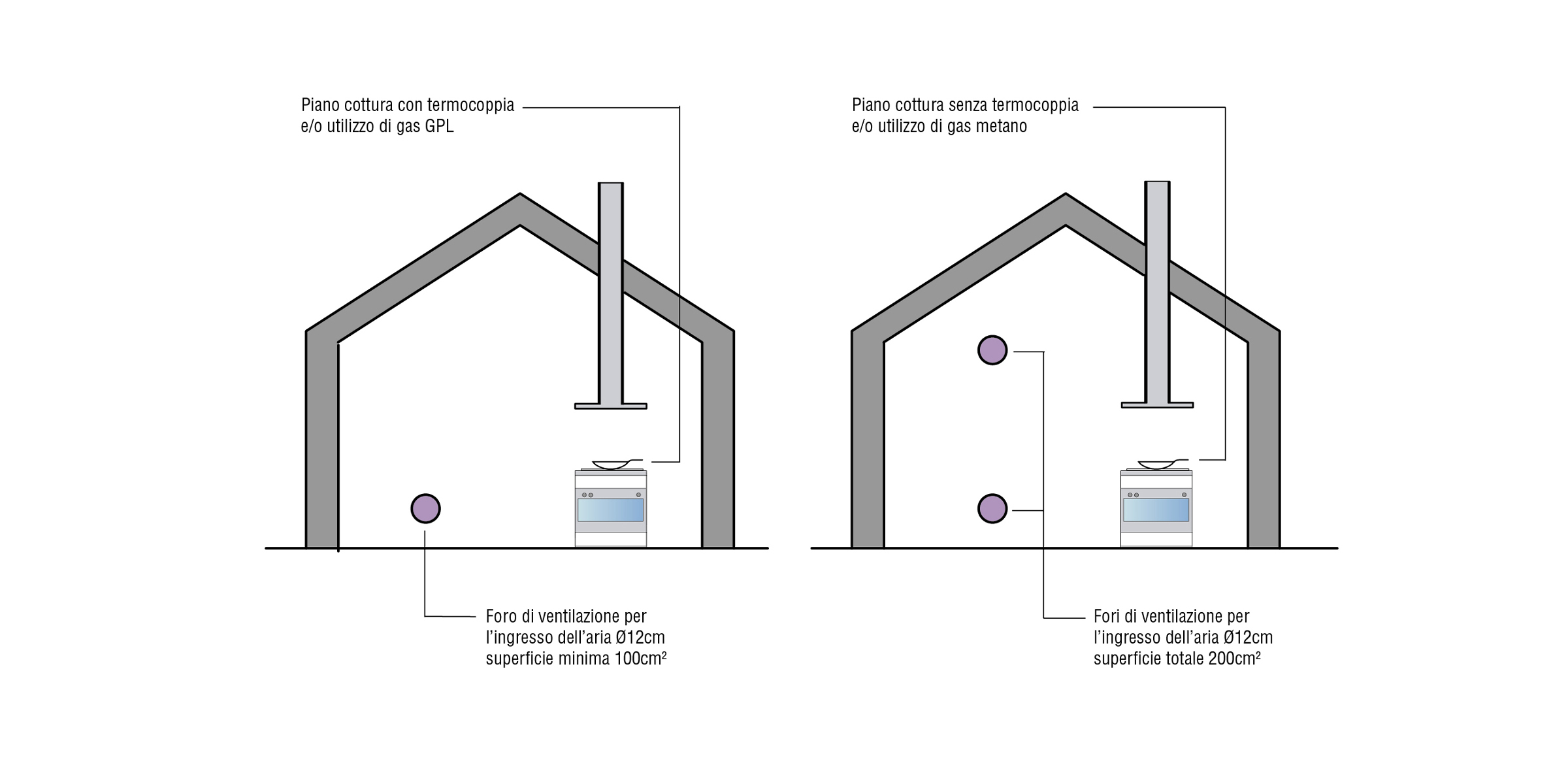

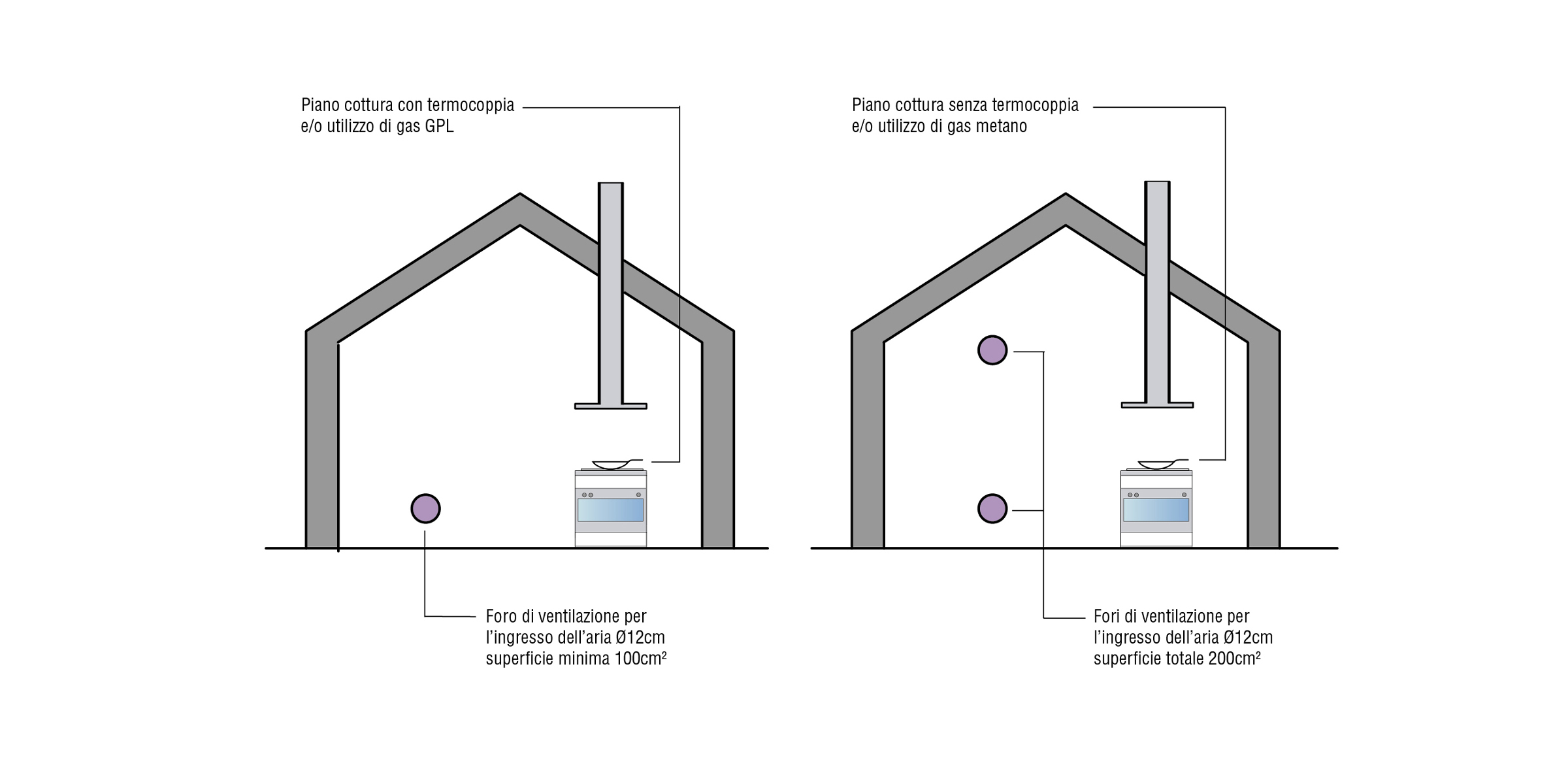

The quantitiy of air that enters the kitchen must be at least equal to the air used for normal gas combustion. In addition to this, one must consider that without a flow of air from outdoors, hood extraction may generate a drop in pressure that would prevent the complete expulsion of fumes. To avoid these two problems the air flow must come in directly through permanent openings on the outside walls of the kitchen. These openings are governed by the UNI7129 standards and must comply with the following requirements:

- they must have a net cross-section of at least 6cm for each kW of heat capacity installed, with a minimum of 100cm ;

- if the hob does not have a thermocouple (device that stops the gas flow if the flame goes out) an additional hole is required to obtain a minimum aeration cross-section of 200cm.

It is advisable for the second hole to be at the top of the kitchen wall to solve problems connected with the use of LPG which, as well as needing a greater quantity of air for combustion, has a relatively lower density compared to natural gas.

Standards also allow indirect ventilation by taking air from an adjacent room, as long as this room is ventilated directly from outdoors, is not a bedroom and is not at a high risk of catching fire (e.g. a carport, a garage, a warehouse etc.).

In addition to this, the adjacent room must not have a lower pressure compared to the room to be aired because of the presence of an appliance powered by any type of fuel (e.g. a fireplace, a stove, etc.) or of an extraction device for which an air inlet has not been provided. The air can flow in from the adjacent room through permanent openings or, if a door divides the two rooms, it can enter by increasing the gap between the door and the floor (min. 2 cm).

Where possible, Valcucine suggests to make the aeration holes in a room adjacent to the kitchen to avoid annoying cold air draughts (before reaching the kitchen the air has time to warm up) and to prevent odours from going towards other rooms in the home by conveying them in the right direction.

The quantitiy of air that enters the kitchen must be at least equal to the air used for normal gas combustion. In addition to this, one must consider that without a flow of air from outdoors, hood extraction may generate a drop in pressure that would prevent the complete expulsion of fumes. To avoid these two problems the air flow must come in directly through permanent openings on the outside walls of the kitchen. These openings are governed by the UNI7129 standards and must comply with the following requirements:

- they must have a net cross-section of at least 6cm for each kW of heat capacity installed, with a minimum of 100cm ;

- if the hob does not have a thermocouple (device that stops the gas flow if the flame goes out) an additional hole is required to obtain a minimum aeration cross-section of 200cm.

It is advisable for the second hole to be at the top of the kitchen wall to solve problems connected with the use of LPG which, as well as needing a greater quantity of air for combustion, has a relatively lower density compared to natural gas.

Standards also allow indirect ventilation by taking air from an adjacent room, as long as this room is ventilated directly from outdoors, is not a bedroom and is not at a high risk of catching fire (e.g. a carport, a garage, a warehouse etc.).

In addition to this, the adjacent room must not have a lower pressure compared to the room to be aired because of the presence of an appliance powered by any type of fuel (e.g. a fireplace, a stove, etc.) or of an extraction device for which an air inlet has not been provided. The air can flow in from the adjacent room through permanent openings or, if a door divides the two rooms, it can enter by increasing the gap between the door and the floor (min. 2 cm).

Where possible, Valcucine suggests to make the aeration holes in a room adjacent to the kitchen to avoid annoying cold air draughts (before reaching the kitchen the air has time to warm up) and to prevent odours from going towards other rooms in the home by conveying them in the right direction.

Hood hole

How can I hide the hood hose if the outlet is in the wrong place?

When you purchase or rent an old house, it is likely that the fumes outlet will be in a position that is wrong for the new kitchen plan. The above examples give you three possible solutions to conceal the hood hose that is usually considered unsightly.

A - If a flat hose is used it can be camouflaged by a slim shelf. Valcucine does not recommend this hose because its has the disadvantage of being very noisy.

B - If a normal-sized hose is used, it can be concealed by an overshelf with a raised front edge.

C - Alternatively, a plasterboard beam or false ceiling can be built.

N.B.: If you are renovating a house we suggest you widen the outlet to a diameter of at least 12cm or, if possible, to make one in the right position for the hood to avoid the need for a visible connecting run.

Furthermore, great care must be paid to avoid using the exhaust pipe of the gas boiler or of the fireplace for the hood.

When you purchase or rent an old house, it is likely that the fumes outlet will be in a position that is wrong for the new kitchen plan. The above examples give you three possible solutions to conceal the hood hose that is usually considered unsightly.

A - If a flat hose is used it can be camouflaged by a slim shelf. Valcucine does not recommend this hose because its has the disadvantage of being very noisy.

B - If a normal-sized hose is used, it can be concealed by an overshelf with a raised front edge.

C - Alternatively, a plasterboard beam or false ceiling can be built.

N.B.: If you are renovating a house we suggest you widen the outlet to a diameter of at least 12cm or, if possible, to make one in the right position for the hood to avoid the need for a visible connecting run.

Furthermore, great care must be paid to avoid using the exhaust pipe of the gas boiler or of the fireplace for the hood.

Check Valve

Why do I need a check valve?

For all its hood models, Valcucine has adopted a special check valve that shuts when the motor is off, preventing unwanted air from flowing in from outdoors, and opens automatically when the motor is on. Unpleasant inconveniences may occur in absence of this valve.

Due to particular circumstances that may occur in the home (draughts or drops in pressure) if the fumes outlet hole is near other flues it may take in the toxic gasses coming from the fireplace, stove or boiler of adjacent homes.

Furthermore, if a check valve is not installed, cold air may come in from outdoors.

Furthermore, due to the chimney effect, a hood without a check valve tends to extract the hot air from the room and convey it oudoors even when it is off, thus incresing heating costs.

In a multi-storey building, all the fumes are usually conveyed into a common flue pipe and then discharged outdoors. The flue pipe must comply with the UNI EN 1443 standard construction requirements. It must also be heat-insulated to prevent condensation or cooling of fumes and it must run vertically and be without constrictions.

The hood flue pipes must run into a common flue pipe that is branched and used to this aim only.

A problem that must not be underestimated is the possible use of an extraction hood without a check valve. In this case, a flue pipe used in common with other homes may attract the fumes and food odours of neighbouring kitchens into your kitchen.

If your hood does not have an integrated check valve, we suggest you install a separate one-way valve in the outside wall.

For all its hood models, Valcucine has adopted a special check valve that shuts when the motor is off, preventing unwanted air from flowing in from outdoors, and opens automatically when the motor is on. Unpleasant inconveniences may occur in absence of this valve.

Due to particular circumstances that may occur in the home (draughts or drops in pressure) if the fumes outlet hole is near other flues it may take in the toxic gasses coming from the fireplace, stove or boiler of adjacent homes.

Furthermore, if a check valve is not installed, cold air may come in from outdoors.

Furthermore, due to the chimney effect, a hood without a check valve tends to extract the hot air from the room and convey it oudoors even when it is off, thus incresing heating costs.

In a multi-storey building, all the fumes are usually conveyed into a common flue pipe and then discharged outdoors. The flue pipe must comply with the UNI EN 1443 standard construction requirements. It must also be heat-insulated to prevent condensation or cooling of fumes and it must run vertically and be without constrictions.

The hood flue pipes must run into a common flue pipe that is branched and used to this aim only.

A problem that must not be underestimated is the possible use of an extraction hood without a check valve. In this case, a flue pipe used in common with other homes may attract the fumes and food odours of neighbouring kitchens into your kitchen.

If your hood does not have an integrated check valve, we suggest you install a separate one-way valve in the outside wall.

Kitchen Hood Duct

How can I plan the fumes outlet to hide the hood duct?

If you plan the fumes outlet and the electric cable outlet at the right height, you can avoid the connecting hose and the socket, that are often not a pleasant sight, from being visible. The examples of flue outlet and power supply cable positions shown in the drawings on the next pages refer to Valcucine patented hoods. For different hoods, the exact measurements must be requested from the manufacturer.

For back-to-wall kitchens the height of the fumes outlet hole will be calculated by adding a variable height that depends on the type of hood, to the height of the base unit and of the back panel. The electric cable outlet must be calculated by taking as a reference point the height of the top edge of the hood and increasing it by 5cm for safety’s sake. This way the electric socket will also be concealed.

For island hoods, the position of the flue outlet in the ceiling must be calculated as follows: lengthwise it must be centred over the hob; crosswise it must be located at a distance from the edge of the base unit that varies depending on the type of hood.

If you plan the fumes outlet and the electric cable outlet at the right height, you can avoid the connecting hose and the socket, that are often not a pleasant sight, from being visible. The examples of flue outlet and power supply cable positions shown in the drawings on the next pages refer to Valcucine patented hoods. For different hoods, the exact measurements must be requested from the manufacturer.

For back-to-wall kitchens the height of the fumes outlet hole will be calculated by adding a variable height that depends on the type of hood, to the height of the base unit and of the back panel. The electric cable outlet must be calculated by taking as a reference point the height of the top edge of the hood and increasing it by 5cm for safety’s sake. This way the electric socket will also be concealed.

For island hoods, the position of the flue outlet in the ceiling must be calculated as follows: lengthwise it must be centred over the hob; crosswise it must be located at a distance from the edge of the base unit that varies depending on the type of hood.

Quiet Kitchen Hood

How can silent extraction be achieved?

The heart of the hood is the motor which determines its extraction capacity. For good extraction, the power of the motor must be suitable for the shape, type and size of the hood.

The motor can be fitted inside the hood. In this case, to reduce its noise level, it must be a top quality one. If you want to further reduce noise, a remote motor can be installed outside, taking care to fit a duct that avoids air vortex formations that could make the hood very noisy.

All Valcucine hoods have an inside motor of at least 750m (volume of air extracted in an hour). If the hood is particularly large, the power is increased by fiitting two motors.

On request, all Valcucine hoods can be fitted with a remote motor instead of an inside one.

For excellent results, Valcucine recommends the use of a remote motor of the same brand as the extractor hood.

The heart of the hood is the motor which determines its extraction capacity. For good extraction, the power of the motor must be suitable for the shape, type and size of the hood.

The motor can be fitted inside the hood. In this case, to reduce its noise level, it must be a top quality one. If you want to further reduce noise, a remote motor can be installed outside, taking care to fit a duct that avoids air vortex formations that could make the hood very noisy.

All Valcucine hoods have an inside motor of at least 750m (volume of air extracted in an hour). If the hood is particularly large, the power is increased by fiitting two motors.

On request, all Valcucine hoods can be fitted with a remote motor instead of an inside one.

For excellent results, Valcucine recommends the use of a remote motor of the same brand as the extractor hood.

Kitchen Hood Height

What is the right hood size for good extraction?

THE DEPTH OF THE HOOD

A - very often, a 80 cm deep kitchen is fitted with a less deep extractor hood (50cm deep) that does not extract fumes well.

B - For the 80cm depth, Valcucine offers hoods with shapes and dimensions that are sufficient to completely cover the cooking area thus ensuring better extraction.

THE WIDTH OF THE HOOD AND THE HEIGHT OF THE WORKTOP

A - If the width of the hob is greater or equal to the hood, vapours and odours cannot be completely extracted, especially if the hood does not have a powerful motor. For safety reasons the hood must not be installed less than 65cm above the hob.

B - If a hood wider than the hob is installed, extraction is improved and the aesthetic result is definitely more attractive because the hood can become a feature and design element that distinguishes the kitchen.

THE DEPTH OF THE HOOD

A - very often, a 80 cm deep kitchen is fitted with a less deep extractor hood (50cm deep) that does not extract fumes well.

B - For the 80cm depth, Valcucine offers hoods with shapes and dimensions that are sufficient to completely cover the cooking area thus ensuring better extraction.

THE WIDTH OF THE HOOD AND THE HEIGHT OF THE WORKTOP

A - If the width of the hob is greater or equal to the hood, vapours and odours cannot be completely extracted, especially if the hood does not have a powerful motor. For safety reasons the hood must not be installed less than 65cm above the hob.

B - If a hood wider than the hob is installed, extraction is improved and the aesthetic result is definitely more attractive because the hood can become a feature and design element that distinguishes the kitchen.